Industrial 3D Printing

Printer built for the highest industrial requirements IDEX system for 24/7 series production

Open software (Orca and Klipper) Large FDM parts up to 800 mm

Industry solution for rail and aviation

Request a 3D Printer Request FDM Print Service Buy Filaments

We are a manufacturer of industrial 3D printers and a printing service provider based in Austria.

Our products

We develop and manufacture 3D printers for the most demanding industrial requirements. These are equipped with a powerful IDEX system for cost-efficient implementation of your small series production. Our customers receive an open system with the latest software such as Orca and Klipper.

Our services

As a manufacturer of FDM 3D printers, we are experts in series production. We produce FDM components up to 600 mm in series for our customers. Using certified materials, we offer an industry solution for rail and aviation.

500+

Customers

Years of Experience

FDM Printer for Printing Service

Technical Filaments

Max. Length of Printed Parts

FAQ – Questions and answers about industrial 3D printing

Industrial 3D printing is designed for maximum precision, repeatability, and material quality. Unlike conventional 3D printing, which is mostly used in private or semi-professional applications, professional hardware with extensive process control is used here.

The aim is not only to manufacture prototypes, but also to produce functional end components. Industrial facilities offer larger construction volumes, enable automated processes, and meet industry-specific standards, for example in mechanical engineering or aviation.

High-performance materials that meet specific mechanical, thermal, or chemical requirements are used in industrial environments. A wide variety of additive manufacturing processes allow for a large selection of materials, including metals and fiber-reinforced materials.

FDM 3D printing uses thermoplastics such as ABS, PA, and PC, which melt at higher temperatures. The exact selection depends on the application—whether for heat-resistant components, high-strength functional parts, or lightweight structures with high load-bearing capacity.

Industrial 3D printing systems achieve very high dimensional accuracy – depending on the process, this is often ±0.1 mm or better. There are processes that offer particularly good surface quality, such as selective laser sintering (SLS) or laser melting (SLM), and processes that combine high printing speed with a good surface finish. In addition, automatic calibration and process monitoring ensure consistently high component quality. This makes industrial 3D printing ideal for functionally critical components in larger quantities.

Yes, definitely. Modern industrial 3D printing processes enable cost-effective series production — especially for small and medium series. The elimination of tooling costs and short lead times allow products to be manufactured quickly and flexibly. Design changes do not require new tools, making iterative development or variant production very efficient. In addition, 3D printing processes allow for complex, functionally integrated geometries that would be difficult or impossible to produce using traditional methods.

In particular, the FDM technology used by NEVO3D enables cost-effective series production thanks to its speed advantages and low material costs.

FDM stands for “Fused Deposition Modeling.” FDM is probably the most commonly used process in additive manufacturing. In this 3D printing process, thermoplastic material is melted in an extruder head. The liquefied material is pressed out of a nozzle and fused with the underlying material by moving the extruder head in defined paths. The process takes place layer by layer, i.e., first the lowest part or base of the desired component is printed onto a print bed. The next layer is then placed on top of this. The desired object is created by continuously printing or fusing the individual layers on top of each other.

The term FFF, which stands for “fused filament fabrication,” is often used as a synonym for FDM.

Industrial 3D printing is used in numerous industries: in the railway and aviation industries, parts with special fire protection requirements are produced, while in the automotive industry, complex tools or functional components are manufactured. Medical technology uses 3D printing for patient-specific implants or prostheses. In mechanical and plant engineering, electronics manufacturing, and even in the consumer goods industry, 3D printing offers new design freedom and accelerated product development. It is increasingly supplementing or replacing conventional manufacturing methods in these areas.

FDM print service from the manufacturer

How can we deliver your production order fast, with premium quality, and at truly unbeatable rates? Because as both the developer and manufacturer of our own 3D printers, we combine unrivaled expertise with the lowest printing costs on the market.

Request FDM service directly from the manufacturerFilaments for professional use

Our high-performance filaments are perfectly matched to our 3D printers – and vice versa. A true win-win. Benefit from professional-grade filaments that deliver outstanding print quality and process reliability – all at highly attractive prices.

Order professional filamentsOur Products

Industrial 3D Printer

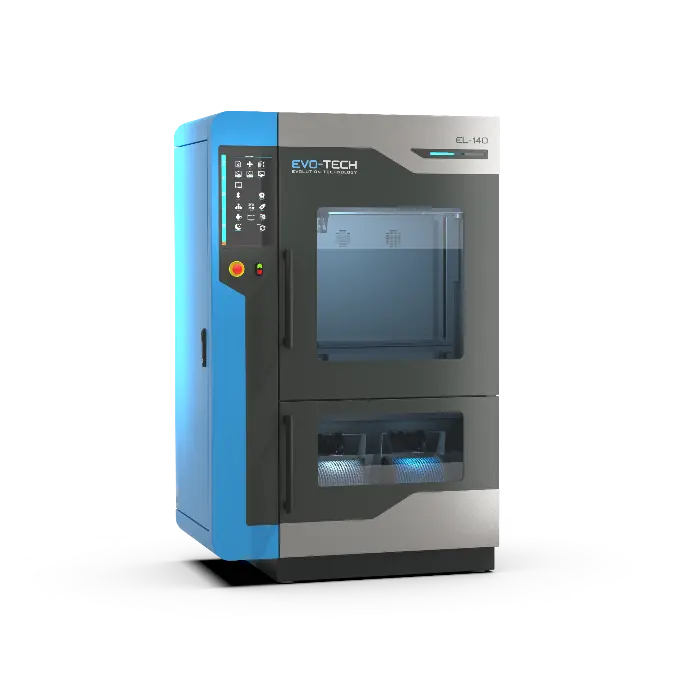

EL-140

Your all-rounder for industrial series production

- Heated chamber (100°C): 570 x 450 x 570 mm (140 liters)

- IDEX system with two extruder heads and REVO HighFlow nozzle

- Automatic bed measurement and Z0 calibration using a beacon sensor

Our Customers

Flexible use of materials – we have the choice!

The open 3D printing systems with their own material profiles give us the flexibility to use materials from other manufacturers as well. This allows us to achieve even greater diversity and optimization in our production processes.

Fast service and excellent customer support – all from a single source!

Thanks to the complete solution comprising software, printers, materials, and support, we always receive fast and reliable assistance. This enables us to organize our production efficiently and on schedule.

The solution for our industrial applications!

The combination of industrial-grade technology, flexible material options, and outstanding support makes NEVO3D our preferred and long-standing partner for demanding industrial applications.

Need more information? We are happy to help you.

Next event: Formnext exhibition, November 18–21, 2025

Experience NEVO3D live. Here's what you can expect: Industrial 3D printers in operation Experience the latest products directly at the booth Information about our FDM print service Upgrades for existing customers Material and print samples

Would you like to discuss the latest developments in professional 3D printing with our experts?

Are you interested in scheduling an appointment for a free consultation?