Industrial FDM 3D printers for large parts and series production

Reduce your production costs while increasing your flexibility.

Join over 500 customers already relying on our industrial 3D printers. Get in touch today and gain your competitive edge with a professional FDM 3D printer from NEVO3D.

Series production of large components is expensive and slow ...

With our industrial 3D printers, you can manufacture functional components in hours instead of days – without compromising on quality and stability.

Our main advantages

Unlock your competitive edge with an industrial 3D printer from NEVO3D.

Large build volume for parts up to 800 mm long

A heated print chamber of up to 200 liters allows you to print really large parts.

Durable, robust design for series production and 24/7 operation

The use of industrial components and a focus on stability characterize the design of our 3D printers.

High-performance filaments for industrial applications

Technical plastics with fiber reinforcement, fire protection, or for applications sensitive to electrostatic energy.

With these industrial 3D printers, you can produce your large-format prototypes and series parts quickly and efficiently.

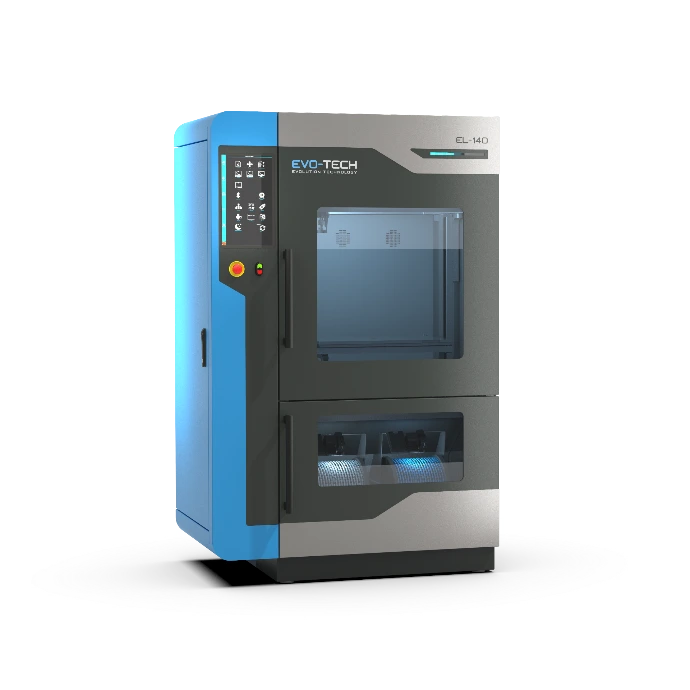

Industrial 3D printer

EL-140

Your all-rounder for industrial series production

Key features:

- Heated chamber (100°C): 570 x 450 x 570 mm (140 liters)

- IDEX system with two extruder heads and REVO HighFlow nozzle

- Automatic bed measurement and Z0 calibration using a beacon sensor

Industrial 3D printer

Next Gerneration

Flagship model for industrial series production

Key features:

- Even bigger heated chamber

- Innovative drive system for optimum surface quality

- Water cooling directly at the print head

Request your free, no-obligation quote for an industrial 3D printer today.

Our industrial 3D printers are trusted by these customers.

With over 10 years of experience in industrial 3D printing, NEVO3D has built a strong reputation. During this time, we have earned the trust of our customers not only with professional 3D printers, but also through our printing services and expert consulting.

NEVO3D's open 3D printing systems with customizable material profiles give us the choice to use filaments from different manufacturers. This enables even greater flexibility and optimization in our production.

Comparison & advantages

How do our industrial 3D printers outperform comparable products?

Open System

At NEVO3D, we are fully committed to open systems — for example with open-source, free software and firmware.

Closed Systeme

Competing systems frequently create dependency by forcing customers to use proprietary, paid software.

Free choice of materials

Our customers enjoy full material freedom — choose from our professional, tested filaments or use your own materials from any manufacturer.

Only materials from the manufacturer

Andere Systeme lassen sich oft nur mit dem Material des Herstellers betreiben, alternative Filamente werden aktiv blockiert. Zusätzlich kosten diese herstellerspezifischen Materialien oft ein Vielfaches der frei am Markt verfügbaren Produkte, was durch ihre Qualität nicht gerechtfertigt ist.

Attractive price

With purchase costs starting at just €50,000 to €80,000 and exceptionally low material prices, our systems deliver one of the lowest Total Costs of Ownership (TCO) in the industry.

Very high investment costs

So-called industrial printers are often priced at €150,000 or more. When paired with overpriced proprietary materials, cost-efficient series production is simply out of reach.