Professionelle FDM 3D Drucker für die Industrie

Druckergrößen

Filamente

Slicer

Bauraumtemperatur

Unsere 3D Drucker für industrielle Anwendungen

EL-40

Der Einstieg in den Industriedruck

AB 27.467€

Netto

- Build size: 400 x 260 x 400 mm

- Print volume: 40 Liter

- Print bed temperature: up to 150°C

- Nozzle temperature: up to 360°C

- Buildchamber heating: 60°C

- Automatic XYZ calibration

- Closed loop axis system

- Filament run-out sensor

- Filament drying

- Filament spool size: 1 to 10 KG

- Soluble support material

- IDEX Düsensystem

- Nozzle cleaning station

- Copymode

- Webcam

- Wasserkühlung

- Magnetic clamping system

- Peak power consumption: 2,700 watts

- Ø Leistungsaufnahme: 900 Watt

- Electrical connection: 230 volts

- Weight: approx. 170 KG

- Boxmaße: 176 x 100 x 89 cm

EL-140

Profi für die Serienfertigung

AB 76.692€

Netto

- Build size: 570 x 450 x 570 mm

- Print volume: 140 Liter

- Print bed temperature: up to 160°C

- Nozzle temperature: up to 420°C

- Buildchamber heating: 100°C

- Automatic XYZ calibration

- Closed loop axis system

- Filament run-out sensor

- Filament drying

- Filament spool size: 1 to 10 KG

- Soluble support material

- IDEX Düsensystem

- Nozzle cleaning station

- Copymode

- Webcam

- Water cooling

- Vacuum clamping table optional

- Magnetic clamping system

- Peak power consumption: 4,500 watts

- Ø Leistungsaufnahme: 1.300 Watt

- Electrical connection: 400 volts

- Weight: approx. 500 KG

- Boxmaße: 192 x 123 x 89 cm

EL-1040

Die Lösung für großformatige Drucke

Coming soon

...

- Build size: 1.300 x 1.000 x 800 mm

- Print volume: 1040 Liter

- Print bed temperature: up to 160°C

- Nozzle temperature: up to 420°C

- Buildchamber heating: 100°C

- Automatic XYZ calibration

- Closed loop axis system

- Filament run-out sensor

- Filament drying

- Pellets

- Soluble support material

- Pelletsextruder

- Nozzle cleaning station

- Copymode

- Webcam

- Water cooling

- Vacuum clamping table optional

- Magnetic clamping system

- Peak power consumption: 9,500 watts

- Ø Leistungsaufnahme: 4.000 Watt

- Electrical connection: 400V / 32A

- Weight: approx. 2,000 KG

- Boxmaße: TBD

Der EL-140 V3: Upgrade für unseren Allrounder in der Serienfertigung

Key Features unserer industriellen 3D Drucker

Open system

With our EVO-lizer 3D printers, we offer you the best of both worlds. On the one hand, we have an open system that gives full access to all parameters and allows you to use your own materials. On the other hand, we offer you a variety of our own materials including tested parameters.

Your advantages:

- Good predefined parameter sets

- Independence from the manufacturer

- Lower material costs

- Significantly cheaper “Total Cost of Ownership”

- Open component programming

Große Materialvielfalt

Whether ESD, soft, hard, UV or heat-resistant - with our 16 materials we always have the right filament solution for you. If this is not the case, you can always use filaments from third-party providers thanks to our open systems.

Your advantages:

- Predefined parameter sets

- Erprobte Hochleistungs-Filamente

- bis 10kg Spulen

Vollautomatische XYZ Kalibrierung

Durch einen integrierten Werkzeuglängensensor können wir nicht nur die Düsenhöhe, sondern auch noch die X und Y Abweichungen der Düsen zueinander vermessen.

Your advantages:

- Fully automatic calibration

- High process reliability

- High reproducibility

- No more test prints necessary after changing nozzles

- Bessere Dual-Druckergebnisse

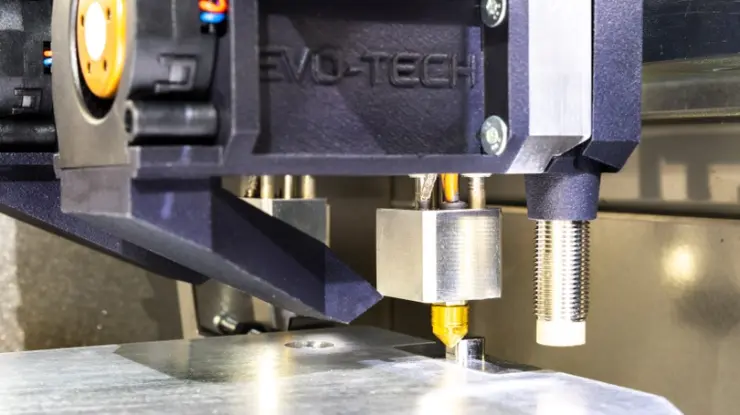

Anti-oozing station for drip-free dual printing

The oozing station prevents material from leaking from one nozzle while another nozzle is printing. This prevents so-called oozing (stringing and dripping on the components).

Your advantages:

- Very good surface quality with dual printing

- High reproducibility

- No material decomposition in the nozzle

- Significantly less cleaning effort

- Shorter printing times

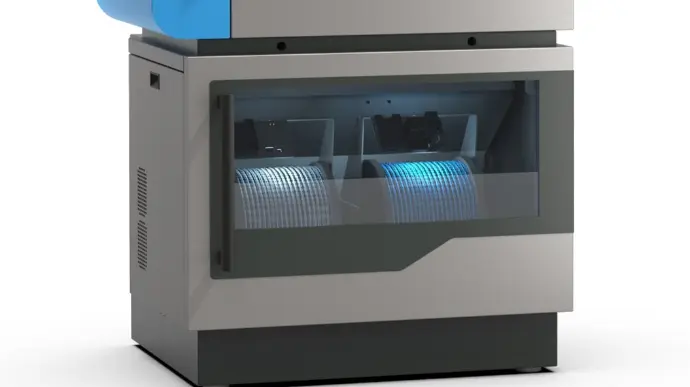

Heated and dried filament chamber

Many filaments absorb humidity from the environment, which can lead to significantly poorer printing results and even print failures. With our integrated drying chamber and its sensors, you can always keep an eye on the moisture and thus increase the quality of your components!

Your advantages:

- Better print quality

- High reproducibility

- Less waste with up to 10 kg of filament

Automatische Druckbettvermessung

Der integrierte, induktive Sensor vermisst vor dem Druckstart vollautomatisch die Ebenheit des Bettes.

Your advantages:

- No manual measuring necessary

- High reproducibility

- Better component adhesion

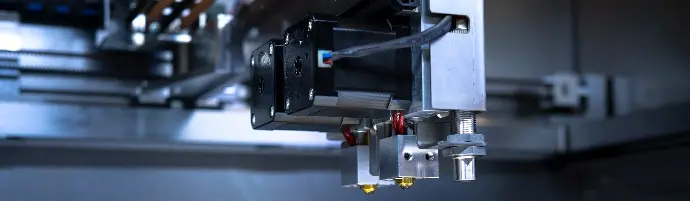

IDEX System

Increase your productivity with up to 4 printheads that can be used at the same time, as well as the associated output and material combination options.

Your advantages:

- Paralleler Druck von 2 gleichen Bauteilen -> Verdoppelung der Druckgeschwindigkeit bei gleichbleibender Bauteilfestigkeiten!

- Combination of different nozzle diameters -> Fine surface quality for external walls and fast output for filling

- Less set-up times when using different materials regularly

- Kombination von 2 Materialien in einem Druckjob

M bis XXL Druckfläche

Your components are not built on sand, but on a neatly milled aluminum plate, which in turn is mounted on a milled steel frame.

Your advantages:

- Prints larger than a Euro pallet are becoming a reality

- Choice between magnetic and/or vacuum clamping system

- Heated printbed minimizes distortion

- No commitment to a manufacturer's proprietary surface material

- Clever linear expansion concept to minimize deformation when heated

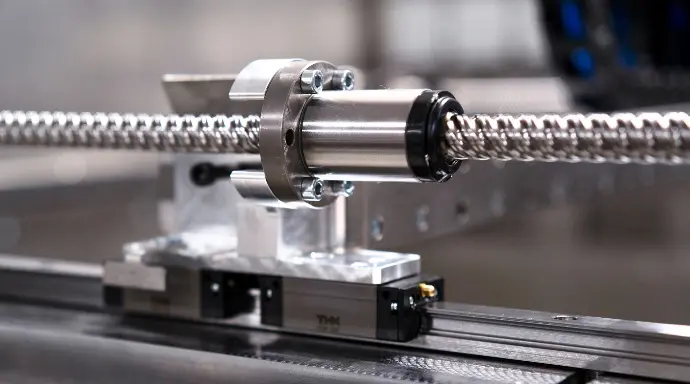

Ball screw, linear guides and reinforced belts

In addition to the design, reproducibility and stability begin with the correct selection of axle components. In 3D printing, in addition to size and dynamics, temperature resistance and linear expansion are also important. With THK we have an industrial partner who can guarantee this.

Your advantages:

- Positioning in the hundredth range

- Low maintenance and wear-resistant

- Hardly any backlash effect

- Industry standard guarantees spare parts availability for decades

- Closed loop drive system

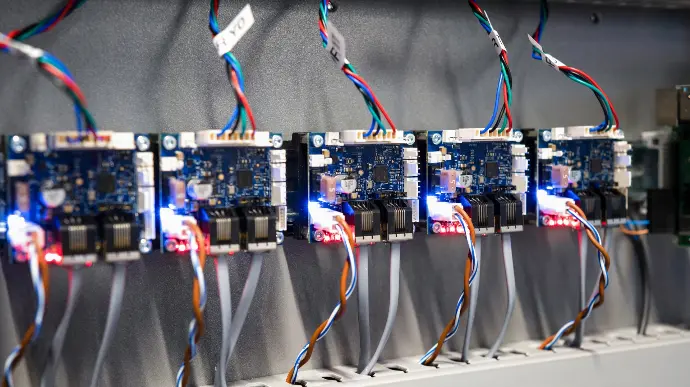

Hardware and software Industry 4.0

Hard- und Software sind für eine intelligente Produktion ausgelegt. Fernzugriff, Echtzeitdaten sowie Automatisierung steigern Ihre Effizienz, Flexibilität und Produktivität.

Your advantages:

- Upgrade security and easy expandability thanks to the modular CAN bus system

- Communication with G-Code standard

- Automatische Updates über Internet oder USB-Stick

- API for reading real-time data

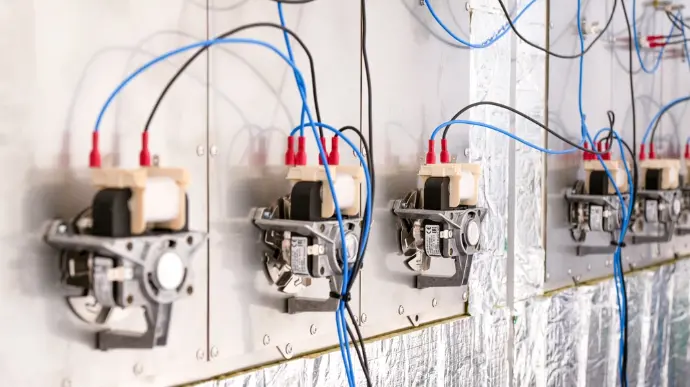

Bis zu 7.200 Watt bringen den Bauraum zum Glühen

When processing plastics in general and in the 3D printing welding process in particular, the process temperatures and controllable cooling are crucial for an excellent result.

Your advantages:

- Significantly less shrinkage and distortion

- Higher component strength

- Verarbeitungsmöglichkeit von Hochleistungs-Materialien

Einfache Wartung & Service

Industrielle 3D Drucker von NEVO3D sind für eine besonders einfache Wart- und Servicierbarkeit optimiert. Abdeckungen die für einen regelmäßigen Zugang abgenommen werden müssen sind beispielsweise magnetisch befestigt.

Your advantages:

- Wartungspunkte ohne Werkzeug erreichbar

(magnetisch befestigte Abdeckungen) - Printhead change within minutes

- Nozzle change in seconds