Main advantages of the FDM 3D printing process

Brief overview

Low costs

FDM printers are available at very affordable prices. The material is also very affordable.

Quick results

FDM printing delivers fast results. There is no need for lengthy preparations or pre-processing.

Material Variety

FDM printing offers the widest range of materials and allows for application-specific manufacturing.

Little rework

If necessary, post-processing consists of breaking off or washing out support structures at most.

Your competitive advantage with FDM 3D printing

Explained in detail

Low total cost

Compared to other 3D printing processes and conventional manufacturing technologies, 3D printing is characterized by relatively low overall costs.

The main reasons for this are:

- Lower acquisition costs for FDM machines: Among the various 3D printing processes, FDM printers are the most affordable.

- Low material costs: Filaments for FDM printing are widely available and very inexpensive to purchase. Compared to powders or liquids, they are extremely easy to store and handle.

- Low personnel costs: In the FDM sector, one person can operate a large number of machines. This is only comparable to a fully automated CNC park.

- Negligible costs for setup and reworking: In addition to simple cleaning tasks, setup for FDM printing usually consists only of replacing filament spools. Reworking is often not necessary at all, but may be required in particular to remove support structures.

Quick results

The availability and setup times of FDM printers are very low. Once the filament is loaded, you can start printing right away. The printing speed is high for 3D printers.

Why FDM enables fast results:

- Easy preparation: Models can be printed directly from 3D data.

- Short setup times: Insert the filament and you're ready to go – start in just a few minutes.

- Direct layer build-up: No additional tools or molds required.

- Prototyping in hours: The first functional components are produced very quickly.

Users benefit from short development cycles and receive immediate feedback on form and function—even without their own 3D printer.

Wide range of materials for FDM 3D printing

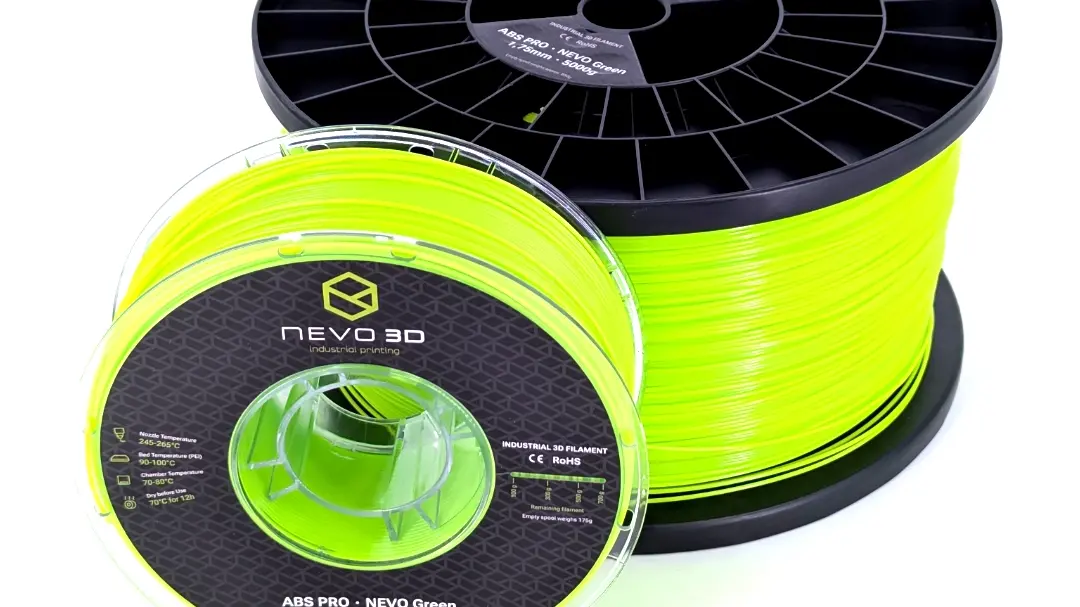

FDM 3D printing offers one of the widest ranges of materials available among additive manufacturing processes. This allows for precise adaptation to any application. Numerous engineering plastics are available that are specifically tailored to mechanical, thermal, or chemical requirements:

- High-performance filaments such as PA or PC, PEEK, or Ultem

- Fiber-reinforced filaments (e.g., PC-CF, PA-GF) for maximum rigidity

- ESD, flame-retardant, or conductive materials for special applications

- Certified materials such as PC-FR according to EN 45545 for specific sectors of the railway industry

Find out more about NEVO3D's high-performance filaments now:

Learn more about professsional filaments von FDM 3D printing

Simple post-processing: hardly any rework

With FDM 3D printing, post-processing is usually limited to “support removal” (removing support material) from more complex components. If no support material is required, there is no post-processing.

The following post-processing steps may be necessary for FDM:

- Removing support material: These support structures are either broken off or washed away, depending on the support material chosen.

- Removing support structures: E.g., removing the brim, which improves bed adhesion between the component and the print bed.

- Post-treatment of edges or surfaces: Deburring the first layer (“elephant foot”) or smoothing ABS using acetone.

For users, FDM printing is a clean and simple manufacturing process that requires little reworking.

How FDM/FFF 3D printing works

The abbreviations FDM (Fused Deposition Modeling) and FFF (Fused Filament Fabrication) both refer to the same additive manufacturing process.

The FDM/FFF 3D printing process is an additive layer-by-layer process in which an object is built up line by line and layer by layer using plastic strips.

The starting material is in the form of filament (wire) with a diameter of usually 1.75 mm on rolls and is transported to the nozzle by motors (extruders). The nozzle melts the filament at 200 to 500°C. The molten filament is pressed through the hole in the nozzle tip (usual diameter 0.2 to 1.2 mm) and “glued” to the underlying print bed or the previous, already solidified layer. The head with the nozzle is controlled and moved by an axis system during the extrusion of the filament. This is what turns the extruded plastic thread into a three-dimensional component. The 3D printer receives the commands for extrusion, movement, and temperature in the form of G-code. The G-code is a long text file that was created from a 3D model before printing. This process is called “slicing” because the 3D model is cut into layers, so to speak, which the 3D printer can then process.

The video clearly illustrates the process using the first EVOlizer EL-11 3D printer from EVO-tech, which was launched in 2013.

More information

You may also be interested in

Open vs. closed systems

In the world of additive manufacturing, there are two fundamentally different machine philosophies among manufacturers. There are those who offer closed systems and only allow their own materials, and those who are open to all materials. At NEVO3D, we try to offer our customers the best of both worlds.

You can find out exactly how these two philosophies differ and how we solved this problem in this article.

Material diversity FDM / FFF

One of the biggest advantages of FDM/FFF technology is the wide variety of materials that can be processed. NEVO3D's open system gives you complete freedom of choice and allows you to use any materials from other manufacturers. We offer our customers application-specific, tested high-performance filaments at attractive prices.

Further information about our materials is available here.

Would you like to learn more about the possibilities offered by 3D printing using FDM technology?

Contact us for a no-obligation consultation on our industrial 3D printers, our printing service, and our selection of professional plastic filaments for your applications and projects.